BOTTLE & CONTAINER

Leak Detection Equipment

Test containers for leaks or neck defects early in your production process.

When plastic containers are manufactured at high volumes, there will be defects in the containers. These containers should be tested early in the production line to verify that the bottle is good before entering other downstream equipment like decorating or filling. Our leak detection systems will test the bottles by measuring the decay of air pressure so we can reject those defective containers.

STANDARD & OPTIONAL

Features of Leak Detection Systems

Our leak detection systems are entirely self-contained and include state of the art valves and circuitry.

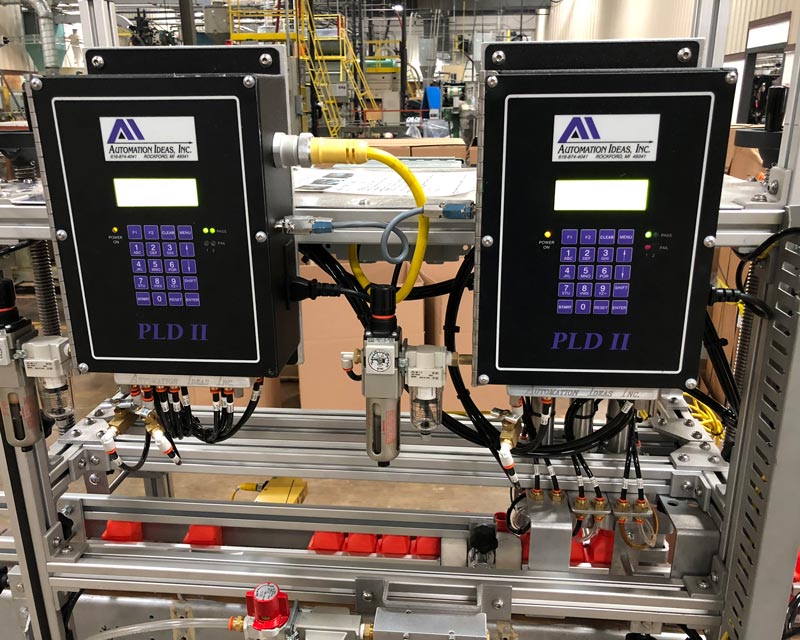

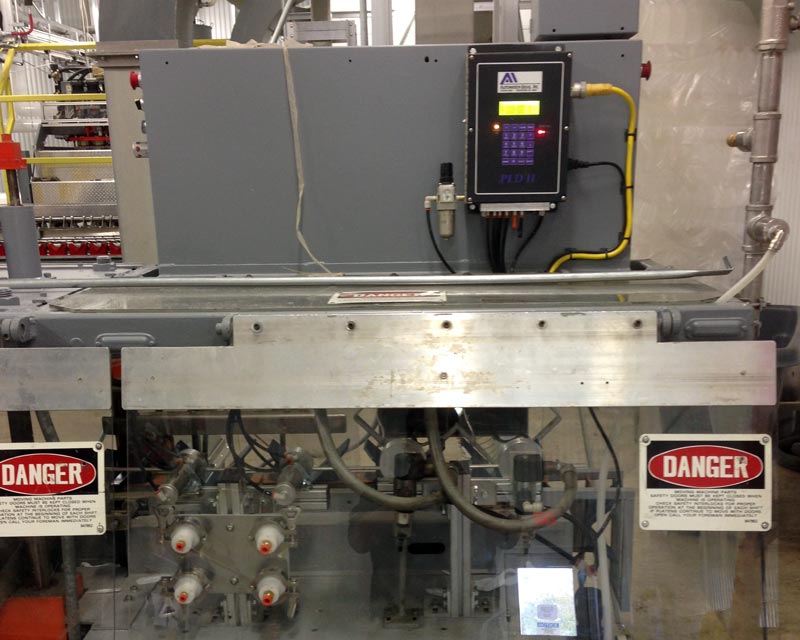

PLDII – Bottle Leak Detector

Trimmer Mount Leak Detectors

Standard & Optional Features

- Available in single or multi head configurations

- Linear or Trimmer mounted

- Custom nose cones to fit any container size

- State of the art controls and color touch screen operator station

- Quick change manifold for air connections

- 110v or 24v power supply options

- Programmable for individual bottle settings for easy changeover

Leak Detection Systems from Automation Ideas

If you are interested in our leak detection systems from Automation Ideas, or would like to learn more about any of our other equipment, please contact us here or give our dedicated support team a call at (616) 874-4041.

Related Equipment

OPTIMIZING YOUR EFFICIENCY

Synchronizing your processes to help minimize downtime in your business!