CONVEYING YOUR PRODUCTS

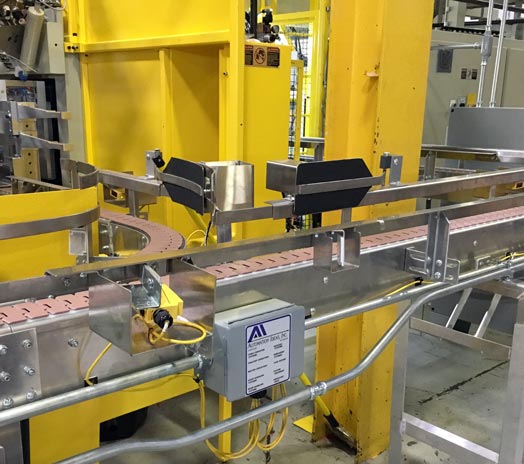

Table Top Conveyors

An excellent solution to conveyor products of any shape and size.

Automations Ideas table top conveyor systems offer a versatile design making it a much sought after conveyor system capable of handling a wide range of products at high-speeds. Our conveyors have many different options and we can customize to your unique application. We can integrate all sorts of equipment on a production line like leak detectors, vision systems, labelers, filling machines, and much more.

Our tabletop conveyor systems are an excellent solution for cans, bottles, containers, jars, glass bottles, , cases, boxes, and much more.

PRODUCT INSPECTION TO CONTAINER FILLING

Table Top Conveyor Systems

Wide variety of industries, which include beverage, pharmaceutical & chemicals.

Optional Features

- Aluminum, Stainless Steel, or Painted Steel Construction

- Washdown Construction

- Available Conveyor Widths: 3.25”, 4.5”, 7.5”, 10”, 12”

- Vacuum Assist

- “Smart System” Controls Package

- Panel view Controls – Screen Upgrades

- Monitor Entire Conveyor System

- iPhone or iPad App Software

- Ethernet or Device Net Connectivity

- Different Voltage Options Available

- Many different conveyor chain styles available

- Fixed or adjustable rails – double or single

- Automatic adjustable rails

- Combiner and divider controls

Table Top Conveyor Systems from Automation Ideas

If you are interested in our table top conveyor systems, or would like to learn more about any of our other conveyors, please contact us here or give our dedicated support team a call at (616) 874-4041.

Related Equipment

OPTIMIZING YOUR EFFICIENCY

Improving your workflow to help minimize downtime in your business!